Volume 18 Issue 3

Latest articles

- Researchpp 5028-5040Gao, Q., You, J., Liao, X., and Wang, Z. (2023). “Identification and analysis of ancient ship wood excavated at Nantong hydraulic site,” BioResources 18(3), 5028-5040.AbstractArticlePDF

The Nantong Ancient Ship refers to an ancient Chinese wooden ship of the late Ming Dynasty excavated in Nantong city in December 2022. This paper identifies the wood and discusses its related analysis. Wood samples extracted from the Nantong Ancient Ship were studied from the viewpoints of anatomy, physics, and chemistry. Microscopic identification results concluded that willow and Chinese fir were the main wood species used to make this ship. The content of holocellulose in the ancient wood was only 37.9 to 38.9%, while the content of lignin was 55.2 to 56.4%. The cellulose crystallinity of ancient wood was 39 to 42% lower than that of healthy recent wood. Fourier transform infrared (FTIR) spectra revealed that the deterioration of ancient wood caused cellulose and hemicellulose degradation, but no apparent lignin alteration. The results could provide a basis for drawing up a conservation plan for the Nantong Ancient Ship. They could also provide a reference for the research and conservation of other archaeological shipwrecks in China.

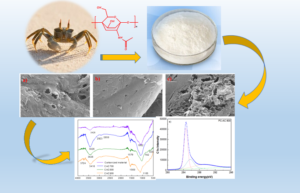

- Researchpp 5041-5056Wang, Y., Ji, Q., and Li, H. (2023). “Preparation, characterization of chitin-based activated carbon for Orange II removal,” BioResources 18(3), 5041-5056.AbstractArticlePDF

Chitin-based activated carbon (CAC) was prepared by a two-step process of carbonization and potassium carbonate chemical activation. The CAC was characterized using scanning electron microscopy (SEM), N2 adsorption/ desorption, Fourier transform infrared (FT-IR) spectroscopy, and X-ray photoelectron spectroscopy (XPS). The adsorption performance of CAC for Orange II (O II) was evaluated in terms of contact time, adsorption temperature, initial concentration, adsorption kinetics, adsorption isotherms, and thermodynamics. The CAC had a surface area of 1320 m2 g-1 and a total pore volume of 1.10 cm3 g-1. The maximum monolayer adsorption capacity was 1010 mg g-1 at 318.2 K for O II, respectively. Equilibrium isotherms showed that the Langmuir model had a higher coefficient of determination than the Freundlich model. The thermodynamic results indicated that the adsorption process of O II onto CAC 800 was spontaneous and endothermic. Given the results of this work, CAC can be used as an efficient adsorbent for the removal of dyes from wastewater.

- Researchpp 5057-5072Tanifuji, K., Sakurai, K., Miyamoto, T., and Okayasu, Y. (2023). “Effect of chemical composition on thermal decomposition behavior of herbaceous plants for production of plant-based biochar for storing carbon in soils,” BioResources 18(3), 5057-5072.AbstractArticlePDF

In order to use plant biomass as biochar for storing carbon in soils, the relationship between the chemical composition of plants and biochar yield obtained by thermogravimetric (TG) analysis was studied. The extractive content of herbaceous plants such as dokudami (Houttuynia cordata), halcyon (Erigeron philadelphicus), and mugwort (Artemisia Spp.) was higher than that of Japanese cypress (Chamaecyparis obtusa), and the yields at 250 and 300 °C tended to decrease with increasing extractive content of plants. This indicated the possibility that thermal decomposition of herbaceous plants can be conducted at low temperatures (below 350 °C). In addition, the content of crystalline carbohydrates (remaining upon treatment with 5% sulfuric acid) of herbaceous plants was lower than that of Japanese cypress, and the yield at 400 °C tended to decrease with increasing crystalline carbohydrate content of plants. This indicated the possibility that herbaceous plants can be used to obtain biochar with higher yield at 400 °C than woody plants. Therefore, herbaceous plants are considered to be feasible resources as raw materials for biochar production for storing carbon in soils.

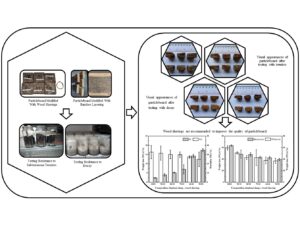

- Researchpp 5073-5084Hartono, R., Sutiawan, J., Hermawan, D., Wibowo, S., and Zulfiana, D. (2023). “Termite and decay resistances of Sumatran elephant dung-based particleboard modified with wood shavings and bamboo layering,” BioResources 18(3), 5073-5084.AbstractArticlePDF

Elephant dung (ED) particleboard (PB) still has subpar physical and mechanical qualities. In earlier research, adding wood shavings and bamboo layers to ED-derived PB successfully enhanced its physical and mechanical qualities. However, the resistance to termites and decay of this PB is still unknown. Therefore, this study examines the resistances to termites and decay of the PBs from ED fiber-modified with wood shavings and bamboo layering. ED and wood shavings were distributed throughout the PB in ratios of 100/0, 90/10, 80/20, 70/30, 60/40, and 50/50 (w/w %). Meanwhile, tali bamboo (Gigantochloa apus), talang bamboo (Schizostachyum brachycladum), kuning bamboo (Bambusa vulgaris), belangke bamboo (Gigantochloa pruriens), and betung bamboo (Dendrocalamus asper) were the materials used in this study. These findings demonstrated that adding wood shavings could improve PB’s resistance to termite and decay attacks. However, in this investigation, the layering of bamboo diminishes the PB’s resistance to termite and decay attack. A 50/50 ratio between ED and wood shavings achieved slightly higher termite mortality and lower weight loss than others. Meanwhile, kuning bamboo had lower termite mortality and higher weight loss than others.

- Researchpp 5085-5095Zamaninasab, S., Lashgari, A., Roohnia, M., Jahan-Latibari, A., and Tajdini, A. (2023). “Fermentation pretreatment and extraction’s effect on the acoustic properties of walnut wood (Juglans regia),” BioResources 18(3), 5085-5095.AbstractArticlePDF

Despite the progress in synthetic polymer industries, wood is one of the main materials in making musical instruments because of its unique characteristics. Many instrument makers try to improve the acoustic properties of wood by traditional treatments. In this study, the changes in the acoustic properties of walnut wood during the processes of fermentation pretreatment, water washing, and organic solvent washings were evaluated. For this, the samples were divided into two groups of 20. For the first group, de-extraction was started with fermentation pretreatment, while the second group samples directly underwent stepwise extraction, using hot water and ethanol-acetone solvents. The results showed a decrease in density, dynamic modulus of elasticity, and damping factor due to the soaking process. But the elastic stiffness did not change. The values of the acoustic coefficient and the acoustic conversion efficiency increased due to the soaking process. The values of density, dynamic modulus of elasticity, elastic stiffness, and damping factor decreased due to ethanol-acetone washing, while the acoustic coefficient and acoustic conversion efficiency showed a significant increase. In general, soaking process and ethanol-acetone washing with fermentation pretreatment improved the acoustic properties of walnut wood.

- Researchpp 5096-5106De, X., Zhang, B., Zhao, J., Guo, W., Zhang, J., Xue, R., and Yang, J. (2023). “Evaluation indexes of poplar sawdust and alfalfa grass forming pellets,” BioResources 18(3), 5096-5106.AbstractArticlePDF

An experimental study was conducted to obtain the degree and pattern of influence of the interaction of various test factors on the evaluation indexes of biomass-forming pellets and the optimal combination of test parameters. Poplar sawdust and alfalfa grass were crushed and compressed into pellets, which were used as test samples. The particle size and moisture contents of the biomass raw materials were selected as test factors, and the quality and performance evaluation indexes, such as relaxation density, Shore hardness, water resistance, crush resistance, longitudinal dimensional stability, forming rate, and productivity, were measured for each pellet group. The results showed that for the same biomass raw material, when the particle size range is zero to 1.5 mm and the moisture content is at 15%, the relaxation density, Shore hardness, and forming rate of the formed pellets are the greatest, and the crush resistance, water resistance, and longitudinal dimensional stability are the strongest. When the particle size range is about 4 to 5.5 mm and the moisture content is at 5%, the relaxation density, Shore hardness, and forming rate of the pellets are the smallest, and the crush resistance, water resistance, and longitudinal dimensional stability are the weakest. The best moisture content of the pellets is about 15%.

- Researchpp 5108-5119Luo, Z., Xu, W., and Wu, S. (2023). “Performances of green velvet material (PLON) used in upholstered furniture,” BioResources 18(3), 5108-5119.AbstractArticlePDF

Green Velvet Material (PLON), which is prepared from polyester slices, has been called a green material based on its ester composition, its ability to be degraded, and the possibility of recovering the value of used material by reprocessing. PLON is expected to be used as a material for the padding layer of upholstered furniture. This paper presented a comparative study of traditional flexible polyurethane foam and Green Velvet Material as the upholstered furniture’s padding layer. The compression mechanical properties of Green Velvet Material and flexible polyurethane foam, such as indentation force deflection, support performance, compression set, and resilience property, were analyzed. The results showed that Green Velvet Material had lower surface hardness and higher comfort compared to flexible polyurethane foam. In terms of resilience, both high-density and low-density Green Velvet Material performed better than the foam control group, but Green Velvet Material had a poorer ability to regain its shape after prolonged pressure. The 30 kg/m3 density Green Velvet Material was the closest to the compression and resilience properties of flexible polyurethane foam. The conclusions provide theoretical data for the effective and reasonable application of Green Velvet Material in upholstered furniture.

- Researchpp 5120-5132Said, K. A. M., Amin, M. A. M., Yakub, I., Rahman, M. R., Kueh, A. B. H., Hamdan, S., and Rahman, M. M. (2023). “Methylene blue adsorption mechanism onto palm kernel shell-derived activated carbon: From particle diffusion to site adsorption,” BioResources 18(3), 5120-5132.AbstractArticlePDF

The mechanism of methylene blue adsorption was investigated for palm kernel shell-derived activated carbon from the bulk solution to active sites. For different initial dye concentrations, 100 ppm methylene blue led to approximately 10 mg/g adsorption capacity while experiencing a decreasing trend at lower initial dye concentrations as follows: 50 ppm (approximately 5 mg/g) > 20 ppm (approximately 2 mg/g) > 5 ppm (approximately 0.5 mg/g). Based on the Boyd external diffusion model, the mechanism of methylene blue adsorption started with its diffusion from the bulk solution via the bounding film encapsulating the activated carbon. The adsorbed species occupied more than one class of active site with an adsorption rate of 0.54 mg/g.min, while the adsorption capacity accounted for 14.7 mg/g. The information about methylene blue offers useful insights into describing the steps of dye adsorption onto palm kernel shell-activated carbon.

- Researchpp 5133-5145Li, S., Zeng, S., Jiang, C., Xu, G., Zhang, Z., and Sun, Q. (2023). “Damage detection of wooden beams based on the modal strain energy change and evidence theory,” BioResources 18(3), 5133-5145.AbstractArticlePDF

A damage detection and localization method for wooden beams was proposed based on the modal strain energy (MSE) change and evidence fusion. The fused damage indicator was deduced using the first three mode shapes of the wooden beams before and after damage. The finite element modal analysis of the free-supported undamaged and damaged wooden beams with different damage severities at one or two locations was performed. The first three mode shapes were extracted from the corresponding modal analysis, with which the damage indicator based on the MSE change and the fused damage indicator of each damage case were computed. The simulation results show that the fused damage indicator accurately detected and located the damage with different severities at one or two locations. Finally, the modal test was completed using the same damage cases as the finite element simulation. The frequency functions of the whole beam were first obtained, with which the first three experimental mode shapes were then acquired, and the damage indicator based on the MSE change and the fused indicator were further computed. The test results verified the validity and reliability of the proposed damage indicator.

- Researchpp 5146-5164Percin, O., and Uzun, O. (2023). “Physical and mechanical properties of laminated wood made from heat-treated Scotch pine reinforced with carbon fiber,” BioResources 18(3), 5146-5164.AbstractArticlePDF

Laminated veneer lumber (LVL) and reinforced laminated veneer lumber (RLVL) with carbon fiber were produced from heat-treated Scotch pine (Pinus sylvestris L.) wood using phenol formaldehyde (PF), polyvinyl acetate (PVAc), and polyurethane (PU) resins. Wood veneers were subjected to heat treatments at 150 °C, 170 °C, or 190 °C for 2 h before lamination. The effects of the reinforcement, heat treatment temperatures, and resins on the properties of the LVL and RLVL were analyzed. Density, equilibrium moisture content (EMC), modulus of rupture (MOR), and modulus of elasticity (MOE) were evaluated. The results showed that MOR and MOE values of solid wood and LVL specimens decreased with increasing treatment temperature. However, reinforcement with carbon fiber increased both MOR and MOE. In addition, the density values of the all RLVL specimens improved, and the EMC altered significantly for all test specimens. Compared to solid samples, the highest MOR values increased by approximately 21% in PF-RLVL samples. Similarly, the highest MOE values increased by 31% in PF-RLVL samples. In conclusion, carbon fiber, one of the most used fabric types in composites, could be utilized in the manufacture of reinforced LVL with heat-treated veneers.