Review Articles

Latest articles

- Reviewpp 4606-4648Emmanuel, O. U., Kuqo, A., and Mai, C. (2021). "Non-conventional mineral binder-bonded lignocellulosic composite materials: A review," BioResources, 16(2), 4606-4648.AbstractArticlePDF

The construction industry suffers from unsustainability and contributes more than any other industrial sector to carbon emissions that lead to global warming. Increasing economic and environmental concerns related to conventional energy- and CO2-intensive building materials have propelled the rapid and sustained expansion of research in the area of plant-based inorganic mineral binder-bonded materials for the construction industry. The resulting composites can be qualified as eco-responsible, sustainable, and efficient multifunctional building materials. So far, most of these research efforts have not received as much attention as materials based on ordinary Portland cement (OPC). To address this gap, this review focuses on mineral binder-based lignocellulosic composites made from non-conventional inorganic mineral binders/ cements with low embodied energy and low carbon footprint, namely hydrated lime-based binders, magnesium-based cement, alkali-activated cement, and geopolymers, as sustainable alternatives to OPC-bonded lignocellulosic composites (state-of-the-art). The emphasis here is on the application potentials, the influence of production parameters on the material properties/ performance, and recent advancement in this field. Finally, a prediction is provided of future trends for these non-conventional mineral binder-bonded lignocellulosic composites.

- Reviewpp 4649-4662Shafiq, M. D., and Ismail, H. (2021). "Multifunctional rubber seed biomass usage in polymer technology and engineering: A short review," BioResources 16(2), 4649-4662.AbstractArticlePDF

Hevea brasiliensis is the most relevant source of natural rubber-based products in the world, and it is mostly found in Southeast Asia. This species is highly functional because its seeds can be utilized as a starting material for many essential applications related to polymer engineering and technology. The main practical compositions are its shell and kernel. The importance of each composition is varied based on the content of each structure. The kernel is predominantly composed of oil, where the oil can be utilized for the production of biofuel and to impart flexibility in many polymer-based composites. Furthermore, the carbon and lignocellulosic contents are heavily represented in the shell of the rubber seed, making the shell useful as a natural resource for carbon-derived applications.

- Reviewpp 6401-6425Bailón-Salas, A. M., Ordaz-Diaz, L. A., López-Serrano, P. M., Flores-Villegas, M. Y., and Dominguez-Calleros, P. A. (2021). "Wastewater as a resource for pest control: An overview," BioResources 16(3), 6401-6425.AbstractArticlePDF

Pests have a negative impact on the economy and the environment. There is an increased urgency for adequate pest control because many pests show high adaptation and climate change has created favorable circumstances for pests. For pest control, synthetic chemicals are used that are lethal to non-target organisms and are toxic to pollinators and aquatic invertebrates. Chemical compounds in plants and derivatives from lignocellulosic materials act against pests. The wastewater from lignocellulosic biomass is a potential source of new compounds with bactericidal, fungicidal, and pesticidal effects that have demonstrated inhibitory activity against plant pathogens. Fungicidal, nematicidal, insecticidal, larvicidal, and bactericidal activities have been proven. Inorganic and organic compounds, such as phenols, aldehydes, esters, and furanics, are the main ones identified. Due to the antimicrobial activity of wastewater, applying it to the soil can modify the composition and structure of key microbial communities. Deep research about richness, biodiversity, functionality, and microbials is needed. This review provides a comprehensive overview of wastewater types that have been applied and possible sources to obtain potential compounds for pest control. Moreover, associated active compounds, recovery techniques, and environmental impacts are reviewed.

- Reviewpp 6426-6447Lee, H., Youn, H., He, M., and Chen, J. (2021). "Back-trap mottle: A review of mechanisms and possible solutions," BioResources 16(3), 6426-6447.AbstractArticlePDF

Print mottle is a serious and common uneven printing defect that occurs when printing coated paper by the offset multicolor printing process. It is characterized by a non-uniform appearance in terms of brightness, gloss, or color density that appears mostly in solid printed areas. Back-trap print mottle and water-interference print mottle occur when the quality of the paper substrate, especially the coating layer quality, is not satisfactory. To cope with this quality problem of coated papers, the understanding of the offset printing process, the requirements of coated-paper quality, and the reasons for this problem should be addressed. In this review, the basic process of offset printing and the mechanisms of print mottles were explored, the importance of coating uniformity in both the coating structure and process was reviewed, and the approaches to cope with print mottle were introduced.

- Reviewpp 6448-6470Aluvihare Gedara, A. K., Chianella, I., Endrino, J. L., and Zhang, Q. (2021). "Adhesiveless bonding of wood – A review with a focus on wood welding," BioResources 16(3), 6448-6470.AbstractArticlePDF

Most industrially used synthetic wood adhesives release formaldehyde, which is carcinogenic for humans. Adhesiveless bonding of wood can be achieved using heat treatment by either hot-pressing method, suitable mainly for wood particles and fibres or by wood welding. Welding of wood, which relies on the heat generated via friction, can be used for bonding two or more solid wood pieces together. The process can be carried out either by linear or rotational wood welding. This review first considers the manufacturing of binderless wood-based panels by hot-pressing. Then this is followed by an in-depth outlook of wood welding and its application in the wood industry. The effects of varying wood welding parameters, such as applied pressure, vibrational frequency and amplitude, holding pressure, holding time, welding time in linear wood welding, and relative diameter difference between the substrate and the dowel in rotational wood welding to obtain joints with optimal mechanical and physical properties is reviewed and discussed. Wood products made by heat treatment (hot-pressing and wood welding) are environmentally friendly, and the brief curing times needed for their manufacture represent a great advantage compared with the usage of wood adhesives to bind pieces of wood.

- Reviewpp 6471-6511Suota, M. J., Kochepka, D. M., Ganter Moura, M. G., Pirich, C. L., Matos, M., Magalhães, W. L. E., and Ramos, L. P. (2021). "Lignin functionalization strategies and the potential applications of its derivatives – A Review," BioResources 16(3), 6471-6511.AbstractArticlePDF

Lignin is one of the most important and widespread carbon sources on Earth. Significant amounts of lignin are delivered to the market by pulp mills and biorefineries, and there have been many efforts to develop routes for its valorization. Over the years, lignin has been used to produce biobased chemicals, materials, and advanced biofuels on the basis of its variable functionalities and physicochemical properties. Today, lignin’s applications are still limited by its heterogeneity, variability, and low reactivity. Thus, modification technologies have been developed to allow lignin to be suitable for a wider range of attractive industrial applications. The most common modifications used for this purpose include amination, methylation, demethylation, phenolation, sulfomethylation, oxyalkylation, acylation or esterification, epoxidation, phosphorylation, nitration, and sulfonation. This article reviews the chemistry involved in these lignin modification technologies, discussing their effect on the finished product while presenting some market perspectives and future outlook to utilize lignin in sustainable biorefineries.

- Reviewpp 6512-6547Chun, Y., Lee, S. K., Yoo, H. Y., and Kim, S. W. (2021). "Recent advancements in biochar production according to feedstock classification, pyrolysis conditions, and applications: A review," BioResources 16(3), 6512-6547.AbstractArticlePDF

Biochar is highly valuable in various applications due to its unique physicochemical properties such as high thermal efficiency, high surface area, surface functional groups, and crystal structure. The goal of this review is to establish a systematic strategy of biochar production for applications in various fields. First, the characteristics of biomass as feedstock for biochar production and their classification are discussed according to the types present in nature. Second, the technology for biochar production and the production yield are examined. In thermochemical conversion for biochar production, five major types of pyrolysis processes are suggested, and the production yield is evaluated according to pyrolysis parameters (feedstock pretreatment, operating temperature, heating rate, residence time, carrier gas). In addition, biochar production from pyrolysis of mixed feedstock has recently been suggested; thus, the evaluation of the production yield from co-pyrolysis is included. Finally, analytical techniques for biochar characterization are investigated and the application of biochar in various fields is considered, such as in adsorbents, energy storage devices, and catalysts.

- Reviewpp 8379-8393Rudak, O., Barcík, Š., Rudak, P., Chayeuski, V., and Koleda, P. (2021). "Densification of wood – Chemical and structural changes due to ultrasonic and mechanical treatment," BioResources, 16(4), 8379-8393.AbstractArticlePDF

This paper presents the state of the art of wood surface densification method by pressing with ultrasound. The properties of ultrasound and its effects on the structure and properties of wood, as well as ultrasound-induced chemical changes in wood material, are described. The following research results were analyzed: the effects of acoustic cavitation in wood material, plasticization of wood lignin by processing with ultrasound, the influence of ultrasound on the wood anatomical structure, the combined effect of ultrasound and wood pressing, and the sterilization of wood using ultrasonic action. Ultrasound causes conversion of lignin from glassy into a quasi-rubbery state, which facilitates compaction of the workpiece surface. Additionally, under ultrasound, growth and collapse of gas bubbles (cavitation phenomena) occur within a liquid medium of wooden substance accompanied by high local temperatures and production of chemically active radicals. This contributes to the destruction of the former and the formation of new bonds in the wood substance, which is important for increasing the stability of the workpiece size after densification. The conclusions made about the ultrasound can be effectively used for the wood plasticization and about prospects of joint use of wood pressing and ultrasound for wood surface densification.

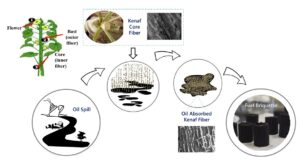

- Reviewpp 8394-8416Tan, J. Y., Low, S. Y., Ban, Z. H., and Siwayanan, P. (2021). "A review on oil spill clean-up using bio-sorbent materials with special emphasis on utilization of kenaf core fibers," BioResources 16(4), 8394-8416.AbstractArticlePDF

Thousands of oil spill incidents regrettably have occurred on a daily basis around the globe. Oil spills are a form of pollution that poses major catastrophic threats to marine ecosystems. Oil spill incidents commonly occur in the middle of the ocean, and the process to remove the oil becomes a great challenge. Absorbents, due to their good oil-absorbing characteristics, are becoming more popular nowadays as one of the effective oil spill clean-up methods. Among the many types of oil absorbents, plant fibers were also being studied to remove the oil spills from the sea surface. This paper reviews factors leading to oil spills, the detrimental effect of the oil spill on the environment, the oil spill removal methods, and the application of plant fibers as oil absorbent material. The paper also will highlight the latest development on the utilization of kenaf core fibers as oil-absorbent material and the use of oil absorbed kenaf core fibers as fuel briquette by taking advantage the high calorific value of the oil spill.

- Reviewpp 8417-8444González, G., and Area, M. C. (2021). "An overview of the obtaining of biomass-derived gamma-valerolactone from levulinic acid or esters without H2 supply," BioResources 16(4), 8417-8444.AbstractArticlePDF

Gamma-valerolactone (GVL) is a highly reactive keto-lactone and a promising platform biomolecule, used as an additive for food and fuels, green solvent, and fuels precursor, among others. Its production from biomass usually involves hydrogenation and subsequent cyclization of levulinic acid or its esters. The process of conventional hydrogenation requires high pressures and temperatures, an external hydrogen source, and scarce noble/precious materials as catalysts. However, it could be produced under mild conditions, using bifunctional metal-acid catalysts with high metal dispersion and meso or microporosity, high surface area, temperatures lower than 200 °C, pressures ≤ 1MPa, and secondary alcohols (such as isopropanol) as hydrogen donors. The catalytic transfer hydrogenation followed by cyclization (CTHC) of levulinic acid (LA) and its esters (LE) to produce GVL using secondary alcohols as H donor is a great alternative. Variables involved in CTHC such as raw material, time, temperature, and type of catalyst, mainly transition metals and their combinations, are reviewed in this work.