Review Articles

Latest articles

- Reviewpp 8445-8456Wu, W., Zhu, J., Xu, W., Han, F., Wu, X., and Wang, X. (2021). "Innovative design of modern mortise and tenon structure under the concept of green reduction," BioResources 16(4), 8445-8456.AbstractArticlePDF

In the furniture industry, some traditional Chinese mortise and tenon joints are not suitable for the current requirements for carbon reduction and environmental protection of furniture products. This article aims to explore new ideas and new methods of modern mortise and tenon structure design. The reduction principle in the green design concept is introduced for the furniture modern mortise and tenon structure design. Based on modern furniture, a systematic analysis of the modern mortise and tenon structure design is carried out. Additionally, this review discusses the method of applying the reduction principle in modern tenon and tenon structure design in the context of green design. The development status and trend of modern mortise and tenon structure design is summarized and an innovative design practice of modern mortise and tenon structure is carried out. The combination of green design and furniture design has important practical significance in a modern context.

- Reviewpp 8457-8488Würfel, H., Geitel, K., Qi, H., and Heinze, T. (2021). "Chemical modification of pectin and polygalacturonic acid: A critical review," BioResources 16(4), 8457-8488.AbstractArticlePDF

Pectin, as a sustainable biopolymer with its two complementary functionalities (carboxyl and hydroxyl moieties) imparted in the α-1,4-galacturonic acid repeating unit, has gained increasing attention in the last few years. The interest in this ubiquitously occurring plant originating polysaccharide (PS) has shifted slowly from applications as a food additive to a broader range of potential applications in medicine, cosmetics, and other industries. Due to the increasing interest in alternatives for petrochemical materials, PSs as biomaterials have gained increasing attention in industrial processes in general. In the last decade, an increasing number of chemical transformations related to pectin have been published, and this is a prerequisite for the design of the structure and hence properties of novel biopolymer-based materials. This work aims to review the chemical modifications of pectin by covalent linkage of the last decade and analyze the materials obtained with these chemical methods critically.

- Reviewpp 8489-8508Moritani, F. Y., Martins, C. E. J., and Dias, A. M. P. G. (2021). "A literature review on cold-formed steel-timber composite structures," BioResources 16(4), 8489-8508.AbstractArticlePDF

State-of-the-art steel-timber composite structures (STC), using cold-formed steel (CFS) and cross-laminated timber (CLT), are considered in this review. Literature on this type of construction solution is reviewed to provide an overview of the characteristics and advantages of STC. Previous experimental and numerical studies with STC structures, mainly composite solutions with CFS beams and CLT panels, are discussed to assess the behavior of this structural typology. A comprehensive description of the connection systems performance in different STC structures is also provided. Furthermore, the design and analytical methods currently available are presented. Likewise, details on aspects related to dynamic properties and fire resistance are discussed.

- Reviewpp 8509-8524Zhang, Z., Fan, Z., Zhang, G., Qin, L., and Fang, J. (2021). "Application progress of microbial immobilization technology based on biomass materials," BioResources 16(4). 8509-8524.AbstractArticlePDF

In recent years, microbial degradation technology has shown broad potential in the fields of agriculture, industry, and environmental protection. However, in practical applications the technology still encounters many problems, such as low bacterial survivability during dynamic operations, the need to remove bacterial liquid, and low tolerance in high-toxic environments, among other issues. Immobilization technology has been developed to overcome such limitations. Microbial strains have been prepared for a specific range of activities utilizing self-fixation or exosome fixation. Immobilization can significantly improve strain density, toxicity tolerance, and bacterial liquid removal. This review first presents the advantages and disadvantages of the current microbial immobilization technologies and then summarizes the properties and characteristics of various carrier materials. The review focuses on how biomass-derived materials have been used as the carriers in new microbial immobilization technologies. The excellent biocompatibility, unique physical structure, and diversified modification methods of biomass-derived materials have shown excellent prospects in the field of microbial immobilization. Finally, microbial immobilization technologies’ potential applications in agriculture, industry, and environmental applications are considered.

- Reviewpp 8525-8566Khandegar, V., Kaur, P. J., and Chanana, P. (2021). "Chitosan and graphene oxide-based nanocomposites for water purification and medical applications: A review," BioResources 16(4), 8525-8566.AbstractArticlePDF

Chitosan (CS) is a natural polysaccharide isolated from insects, molluscs, and fungi. The specific properties of chitosan can be enhanced using physicochemical processes. The composites prepared using CS and graphene oxide (GO) contain active functional groups such as epoxide, carboxyl, and hydroxyl, which possess excellent biocompatibility, high adsorption capacity, and biodegradability. Their low cost and ease of scale-up make them employable for multiple applications in water-treatment plants, electronics, solar cells, and pharmaceuticals. This review provides an overview of sources, types, and properties of chitin, chitosan, and graphene oxide. The use of these composites for the preparation of anti-microbial drugs has been discussed here. The article also explores the applicability of such composites for removal of heavy metals (lead, copper, chromium, cobalt, mercury, etc.), dyes (methylene blue and other reactive dyes), and organic and inorganic contaminants (ofloxacin, naphthanol, phenol, and oil, etc.). The article highlights various knowledge gaps in the field and the scope of future work.

- Reviewpp 8567-8639Hubbe, M. A. (2021). "Energy efficiency challenges in pulp and paper manufacturing: A tutorial review," BioResources 16(4), 8567-8639.AbstractArticlePDF

The pulp and paper industry is highly energy-intensive. In mills that use chemical pulping, roughly half of the higher heating value of the cellulosic material used to manufacture the product typically is incinerated to generate steam and electricity that is needed to run the processes. Additional energy, much of it non-renewable, needs to be purchased. This review considers publications describing steps that pulp and paper facilities can take to operate more efficiently. Savings can be achieved, for instance, by minimizing unnecessary losses in exergy, which can be defined as the energy content relative to a standard ambient condition. Throughout the long series of unit operations comprising the conversion of wood material to sheets of paper, there are large opportunities to more closely approach a hypothetical ideal performance by following established best-practices.

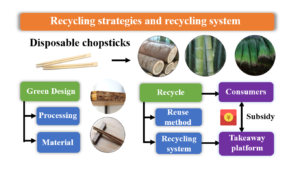

- Reviewpp 8640-8656Fu, Y., and Zhu, J. (2021). "Green design and recycling systems for solving the dilemma of disposable chopsticks waste caused by online food delivery: A review," BioResources 16(4), 8640-8656.AbstractArticlePDF

With the rapid advancement of online food delivery and takeaway markets, the use of disposable chopsticks has exponentially increased in China, resulting in the reduction of forest resources and the generation of large amounts of chopstick waste. This review summarizes a variety of methods to produce eco-friendly chopsticks with the aim of enabling a second life cycle for chopstick waste. The related practical recycling systems and policies based on government experience in developed regions are proposed. Furthermore, perspectives with regard to the future development of waste chopsticks recycling systems are also discussed.

- Reviewpp 1926-1938Dlamini, L. C., Fakudze, S., Makombe, G. G., Muse, S., and Zhu, J. (2022). "Bamboo as a valuable resource and its utilization in historical and modern-day China," BioResources 17(1), 1926-1938.AbstractArticlePDF

Due to some challenges related to the utilization of wood, such as long growth cycles and severe deforestation, the utilization of bamboo resources has attracted wide attention globally. Bamboo is characterized by remarkable strength and elasticity properties, minimal maintenance requirements, and a fast growth cycle, as it can reach maturity within three to five years. Moreover, bamboo is attractive as a sustainable resource owing to its excellent regeneration ability and high crop yield. A single cultivation of bamboo can remain existent for several years, and the plants can regenerate new shoots shortly after harvesting. Hence, the cultivation, management, trade, and utilization of eco-friendly bamboo resources have become of great importance. Currently, a larger proportion of the world’s bamboo forests and approximately 80% of the world’s bamboo species are found in east Asia, south Asia, and southeast Asia. China has the richest bamboo resources, with a total of 861 species from 43 genera. Specifically, bamboo forests in China cover a total area of approximately 6.73 million ha (approximately one-third of the world’s bamboo forests) scattered across different provinces, including Fujian, Jiangxi, Hunan, and Zhejiang, among others. Herein, this work reviewed the cultivation and utilization of bamboo resources in historical and modern China.

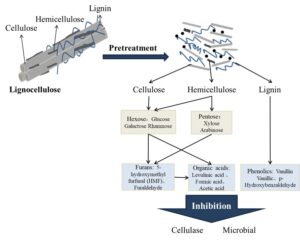

- Reviewpp 1939-1961Luo, X., Zeng, B., Zhong, Y., and Chen, J. (2022). "Production and detoxification of inhibitors during the destruction of lignocellulose spatial structure," BioResources 17(1), 1939-1961.AbstractArticlePDF

Lignocellulosic biomass is a renewable resource that is widely abundant and can be used to produce biofuels such as methanol and ethanol. Because biofuels have the potential to alleviate shortages of energy in today’s world, they have attracted much research attention. The pretreatment of lignocellulose is an important step in the conversion of biomass products. The pretreatment can destroy the crosslinking effect of lignin and hemicellulose on cellulose, remove lignin, degrade hemicellulose, and change the crystal structure of cellulose. The reaction area between the enzyme and the substrate is enlarged, and the yield of subsequent enzymatic hydrolysis and microbial fermentation products is significantly increased. Conventional pretreatment methods help convert lignocellulosic material to sugars, but the treatments also produce some inhibitors, which are mainly organic acids, aldehydes, phenols, and other substances. They may affect the subsequent saccharification and growth of fermentation microorganisms, thereby reducing the bioconversion of the lignocellulose. It is therefore necessary to take effective means of detoxification. This paper reviews lignocellulose pretreatment methods, with an emphasis on inhibitors and their management. A summary is provided of detoxification methods, and the future use of lignocellulosic biomass for fuels prospects.

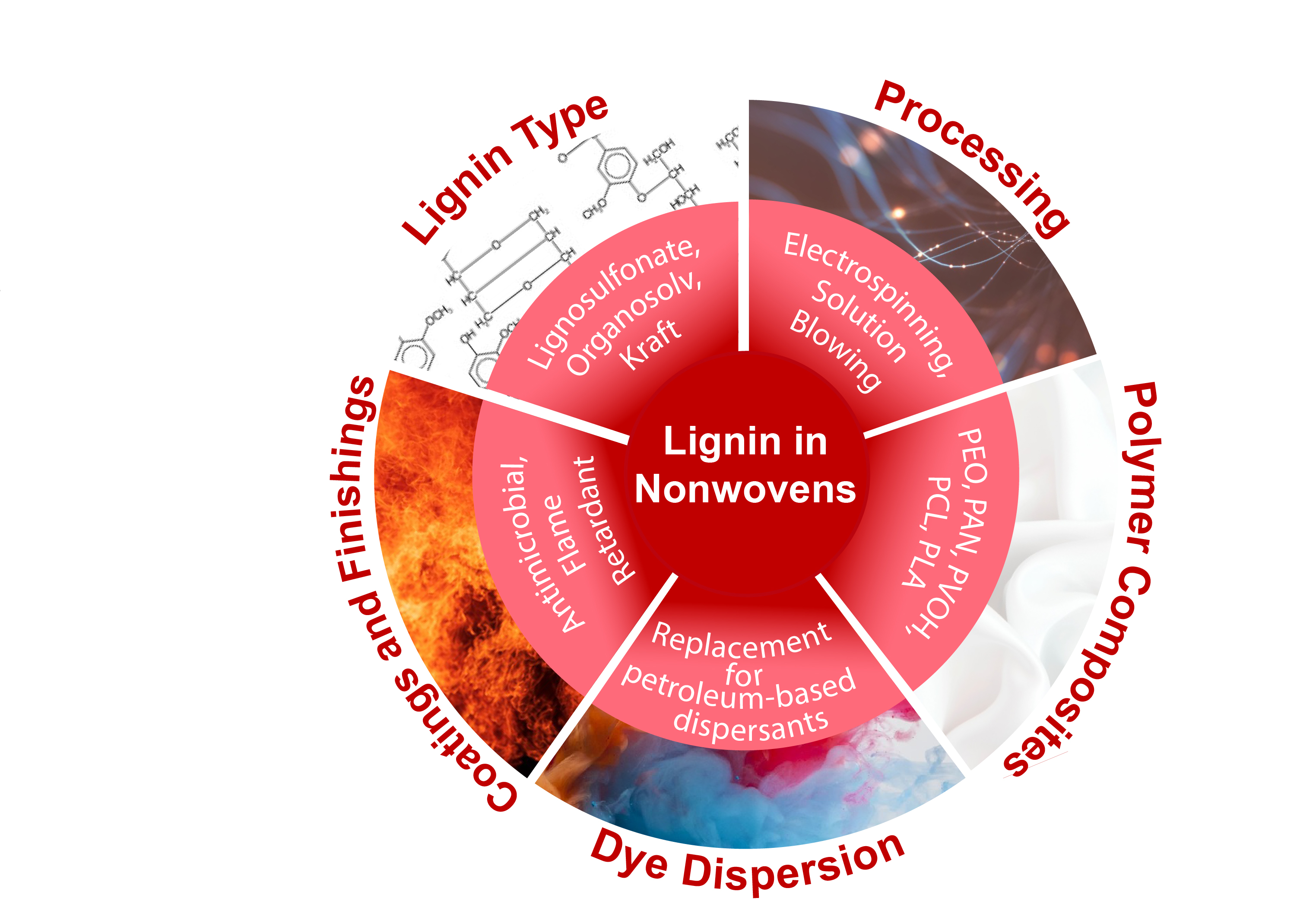

- Reviewpp 3445-3488Gaynor, J. G., Szlek, D. B., Kwon, S., Tiller, P. S., Byington, M. S., and Argyropoulos, D. S. (2022). "Lignin use in nonwovens: A review," BioResources 17(2), 3445-3488.AbstractArticlePDF

While lignin has been gaining wide research interest for a variety of applications across many industries, relatively little work has been published on its applications in nonwovens. Consequently, this article offers an overview of the underlying principles and both the present and future applications of lignin within the nonwoven industry. Due to the distinct structure of lignin, processing, fiber production, composites with polymers, dye dispersant, and fire-retardant applications are all unique opportunities for lignin application in nonwovens discussed in this review. Conventional nonwoven processing techniques, such as electrospinning, have been reported to successfully produce lignin-based nonwovens, specifically lignin/polymer composite nonwovens. This account points to pivotal polymer matrix/lignin composite compatibility issues that define various processing technologies. However, lignin use is not limited to incorporation within nonwoven fibers mats and is currently used in dye dispersion with the potential of phase out petroleum-based dye dispersants. Finally, the high phenolic content of lignin endows it with fire-retardant and antimicrobial properties, among others, that present additional opportunities for lignin in the nonwoven industry. Throughout this review, an effort is made to outline the advantages and challenges of using lignin as a green and sustainable ingredient for the production of nonwoven materials.