Review Articles

Latest articles

- Reviewpp 3489-3508Zhou, Q., Le, Q. V., Yang, H., Gu, H., Yang, Y., Sonne, C., Tabatabaei, M., Lam, S. S., Li, C., Chen, X., and Peng, W. (2022). "Sustainable conversion of agricultural biomass into renewable energy products: A Discussion," BioResources 17(2), 3489-3508.AbstractArticlePDF

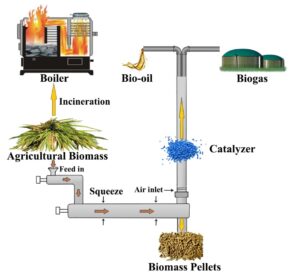

This paper discusses the use of agricultural biomass as a promising resource for renewable energy production, e.g., bio-oil and biogas via pyrolysis and catalysis, among other technologies. In order to prevent the accumulation of agricultural biomass, most countries still use traditional disposal or processing methods, e.g., burning in the field, which not only has a low energy conversion rate, but also releases harmful gases, e.g., CO2, CO, and NH3. These traditional methods are regarded as inefficient with respect to the low utilization of waste; they also pose a threat to human health. The energy conversion of agricultural biomass makes full use of resources and accelerates the development of green energy. In particular, agricultural biomass can lead to the production of high-quality renewable fuels and chemical raw materials through catalytic pyrolysis technologies. The fuel produced using catalytic pyrolysis has a low sulfur and alkali metal contents and techno-economic analysis shows that catalytic pyrolysis greatly reduces the production cost and improves the utilization rate of agricultural biomass. The production of bio-oil and gas via catalytic pyrolysis and agricultural biomass are environmentally friendly and economically feasible for clean energy production. Therefore, additional research is needed to enable the upscaling of renewable energy products.

- Reviewpp 3509-3550Pawlak, J. J., Frazier, R., Vera, R. E., Wang, Y., and Gonzalez, R. (2022). "Review: The softness of hygiene tissue," BioResources 17(2), 3509-3550.AbstractArticlePDF

The hygiene tissue industry has an extensive global market that is quickly growing. Market research has indicated that softness is one of consumers’ most highly desired properties. For certain hygiene tissue products (specifically bath tissue), this property can influence prices. A better understanding of the science of softness would allow companies to engineer soft tissue more economically and efficiently. Softness is a subjective perception related to physical aspects that make it challenging to express and measure. Human handfeel panel testing, which ranks the specimens through physical tests, has been recognized as the most reliable method to measure tissue softness. Much effort has been expanded in correlating the panel test results with some measurable properties. In this regard, equipment has been recently developed by combining several different mechanical, surface, and acoustic properties to characterize softness. In comparison with panel tests, these instruments (e.g., tissue softness analyzer) have been found to give equivalent softness metrics. A combination of materials selection and manufacturing operations are used to create softer tissue sheets. This paper reviews the sensation of softness as perceived by the human touch, techniques for measuring softness, the influence of fiber on softness, manufacturing techniques, and additives used for softness enhancement.

- Reviewpp 3551-3673Szlek, D. B., Reynolds, A. M., and Hubbe, M. A. (2022). "Hydrophobic molecular treatments of cellulose-based or other polysaccharide barrier layers for sustainable food packaging: A Review," BioResources 17(2), 3551-3673.AbstractArticlePDF

Paper, nanocellulose, and other polysaccharide-based materials can be excellent candidates for food packaging barrier layers, except that they tend to be vulnerable to moisture. This article reviews published research describing various chemical treatments having the potential to render hydrophobic character to such layers. Emphasis is placed on systems in which hydrophobic monomers are used to treat either particles or sheets comprised largely of polysaccharides. A goal of this review is to identify combinations of materials and procedures having promise for scale-up to industrial production, while providing effective resistance to moisture. The idea is to protect the underlying polysaccharide-based barrier layers such that they can continue to impede the transfer of such permeants as oxygen, greases, flavor compounds, and water vapor. A further goal is to minimize any adverse environmental impacts associated with the treatments. Based on the research articles considered in this review, promising hydrophobic treatments can be achieved involving silanes, ester formation, other covalent interactions, plasma treatments, and to some extent by various treatments that do not require formation of covalent bonds. The article is designed such that readers can skip ahead to items of particular interest to them.

- Reviewpp 3674-3701Espinoza Acosta, J. L., Figueroa Espinoza, E. G., and de la Rosa Alcaraz, M. (2022). "Recent progress in the production of lignin-based sunscreens: A Review," BioResources 17(2). 3674-3701.AbstractArticlePDF

Technical lignins are becoming an attractive natural, renewable, and non-toxic ingredient in sunscreens, having the capability for replacing synthetic compounds. Researchers have reported that lignin can increase the solar protection factor (SPF) of sunscreens and provide sun protection to body creams. However, to achieve the valorization of lignin in the fabrication of personal care products, it is necessary to overcome several challenges related to their molecular complexity and unattractive color. Fractionation, chemical modification, whitening, particle size reduction, and the synthesis of nanocomposites and copolymers are strategies reported to overcome the lignin challenges in the development of lignin-based sunscreens. This paper summarizes and analyzes previous research studies and outstanding findings (from 2016 to 2022) directed at the reduction of the problems that limit the extensive applications of lignin in skincare products such as sunscreens.

- Reviewpp 3702-3717Cao, S., Cheng, S., and Cai, J. (2022). "Research progress and prospects of wood high-temperature heat treatment technology," BioResources 17(2), 3702-3717.AbstractArticlePDF

High temperature heat treatment is one of the main technologies with the highest market conversion rate and broad future prospects in the functional technology of wood. Chemical reagents are not added in the production process. The treatment improves the dimensional stability, biological durability, wood color, and acoustic properties without reducing the environmental performance of the product. However, there are some problems in heat treatment, such as the reduction of mechanical properties and surface wettability of wood, high production energy consumption, and large exhaust emissions. Therefore, understanding the influence and mechanism of high temperature heat treatment technology on wood properties is of guiding significance to further improve the quality of heat-treated wood, improve production process, and develop new equipment. This article reviews the effects of heat treatment on the properties of wood and the mechanism of heat treatment. Then, some applications of heat treatment of wood are introduced. Finally, the development direction and prospect of high temperature heat treatment technology in the future are forecasted.

- Reviewpp 3718-3780Hashemzehi, M., Mesic, B., Sjöstrand, B., and Naqvi, M. (2022). "A comprehensive review of nanocellulose modification and applications in papermaking and packaging: Challenges, technical solutions, and perspectives," BioResources 17(2), 3718-3780.AbstractArticlePDF

The increasing usage of petroleum-based compounds has prompted numerous environmental concerns. Consequently, there has been a steady rise in research on the synthesis of useful materials from natural sources. Paper technologists are seeking environmentally acceptable dry end and wet end additives. Among the bio-based resources available, nanocellulose is a popular sustainable nanomaterial additive in the paper industry because of its high strength, high oxygen barrier performance, low density, great mechanical properties, and biocompatibility. NC’s extensive hydroxyl groups provide a unique possibility to dramatically modify the hydrophilicity and charge of the surface in order to improve their potential applications in the paper industry. The current paper reviews two series of surface modifications, each with various subcategories, depending on why modified nanocellulose is added in the paper production: to improve barrier properties or to improve mechanical properties of packaging materials. The methods presented in this study use the minimum amount of chemically hazardous solvents to have the least impact on the environment. This review focuses on modifications of nanocellulose and their subsequent application in the papermaking. The knowledge and the discussion presented in this review will form a literature source for future use by various stakeholders and the sustainable paper manufacturers.

- Reviewpp 3781-3809Abd Rahim, N., Indera Luthfi, A. A., Mohamed Abdul, P., Mad Jahim, J., and Bukhari, N. A. (2022). "Towards sustainable production of bio-based lactic acid via a bio-based technical route: Recent developments and the use of palm kernel cakes in the bioconversion," BioResources, 17(2), 3781-3809.AbstractArticlePDF

The continued reliance on non-renewable fossil resources has led to serious environmental issues. In light of these concerns, the transition from non-renewable sources to more sustainable ones have been explored, as exemplified by the production of bio-based lactic acid via lignocellulosic biomass bio-refinery process. Malaysia, the second-largest producer of palm oil in the world, generates abundant, cheap, and underutilized oil palm biomass in the form of palm kernel cakes. Comprised of 50% fermentable hexose sugars, palm kernel cakes have emerged as an interesting feedstock substitute in the production of bio-based fine chemicals, e.g., lactic acid. This paper focuses on current work based on selected literature published in the 21st century on the exploitation of palm kernel cakes as a novel feedstock in bio-refinery processes after addressing the current global demand and potential commodity applications of bio-based lactic acid. It then discusses current research on potential lactic acid-producing microorganisms, with particular attention to bacteria, and different pretreatment methods for carbohydrate recovery from palm kernel cakes. It also highlights the potential of oil palm biomass, especially palm kernel cakes, as a promising commodity that contributes to sugar platforms in value-added products, e.g., biofuel, bioenergy, ethanol, acids, and fine chemicals.

- Reviewpp 3810-3870Debnath, M., Sarder, R., Pal, L., and Hubbe, M. A. (2022). "Molded pulp products for sustainable packaging: Production rate challenges and product opportunities," BioResources 17(2), 3810-3870.AbstractArticlePDF

Molded cellulosic pulp products provide eco-friendly alternatives to various petroleum-based packaging systems. They have a long history of reliable usage for such applications as egg trays and the shipping of fruits. They have recently become increasingly used for the packaging of electronics, wine bottles, and specialty items. Molded pulp products are especially used in applications requiring cushioning ability, as well as when it is important to match the shapes of the packed items. Their main component, cellulosic fibers from virgin or recycled wood fibers, as well as various nonwood fibers, can reduce society’s dependence on plastics, including expanded polystyrene. However, the dewatering of molded pulp tends to be slow, and the subsequent evaporation of water is energy-intensive. The article reviews strategies to increase production rates and to lower energy consumption. In addition, by applying chemical treatments and processing approaches, there are opportunities to achieve desired end-use properties, such as grease resistance. New manufacturing strategies, including rapid prototyping and advances in tooling, provide opportunities for more efficient form factors and more effective packaging in the future.

- Reviewpp 5420-5436Kumar, A., Bharti, A. K., and Bezie, Y. (2022). "Schizophyllum commune: A fungal cell-factory for production of valuable metabolites and enzymes," BioResources 17(3), 5420-5436.AbstractArticlePDF

Schizophyllum commune is a basidiomycete that is capable of producing different valuable metabolites such as schizophyllan-a polysaccharide, ethanol, and lignocellulolytic enzymes. Schizophyllan finds application in the food industry, pharmacy, and oil recovery. It acts as a non-specific stimulator of immune system. It shows bioactivities such as antineoplastic, antibacterial, anti-cancer, anti-inflammatory, and antiparasitic properties. S. commune is capable of producing bioethanol directly in a single step using lignocellulosic biomass. Lignocellulolytic enzymes including cellulase, xylanase, pectinase, laccase, lignin peroxidase, and manganese peroxidase, are also synthesized efficiently by different strains of S. commune. Being a good producer of ligninolytic enzymes, S. commune has been shown to be effective for the degradation of various synthetic dyes. This article reviews the production of schizophyllan, ethanol, and enzymes and the utilization of S. commune for lignocellulose degradation and decolorization of synthetic dyes.

- Reviewpp 5437-5463Kaur, P. J., Yadav, P., Gupta, M., Khandegar, V., and Jain, A. K. (2022). "Bamboo as a source for value added products: Paving way to global circular economy," BioResources 17(3), 5437-5463.AbstractArticlePDF

Bamboo biomass is known for its low cost, abundance, fast growth rate, low weight-to-height ratio, and load-bearing abilities, making it an attractive alternative to materials such as wood, metal, steel, and plastic for multiple applications. Bamboo is traditionally used in handicrafts, food, building, construction, pulp, and paper. The production of energy and green adsorbents with unique properties are a few emerging applications of bamboo. Porous structured, bamboo-based charcoal allows the separation of solute from solvent and can be used to detoxify the air, water, and soil. The surface functional groups can be enhanced during thermal processing, yielding activated carbon products and serving greenhouse gas capturing applications. Nanoparticle particles (Ni0.5Zn0.5Fe2O4 and silver) coated bamboo charcoal has shown microwave and Infrared energy shielding effects. Bamboo-based charcoal also has exceptional medicinal values, is an efficient drug-delivery agent, and has tremendous potential for small and medium enterprises. Bamboo charcoal is also investigated as a toxin adsorber and hence a blood purifier. This review also considers the potential and challenges in using bamboo and its products for many applications that can contribute to a renewable society.